HOME >> PRODUCTS >> Metal Mesh >> Perforated Metal Mesh

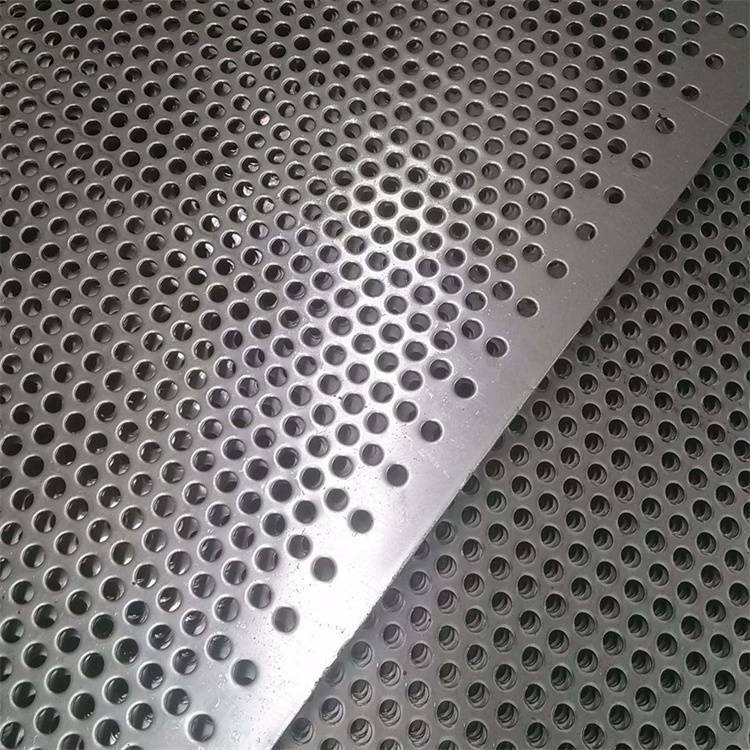

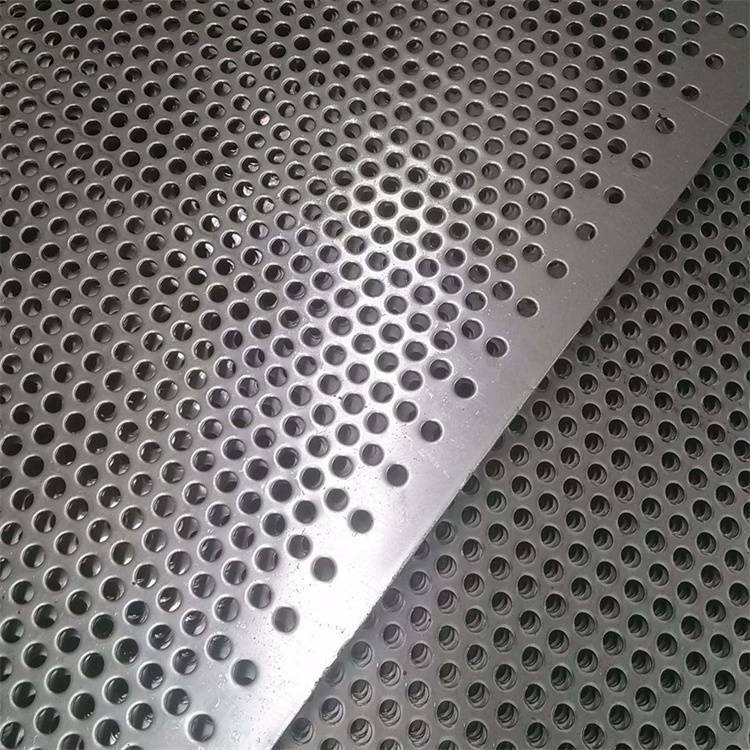

Description: Galvanized Perforated Mesh is a versatile industrial mesh product renowned for its precise hole patterns, excellent structural stability, and wide adaptability. It is widely used in filtration, support, and separation scenarios across multiple industries

Model No.:JH5768PW

Model No.:JH5768PW Supply Nature:Factory Direct

Supply Nature:Factory DirectPRODUCTS

NEWS

Product Details

Galvanized Perforated Mesh is a versatile industrial mesh product renowned for its precise hole patterns, excellent structural stability, and wide adaptability. It is widely used in filtration, support, and separation scenarios across multiple industries, with customizable specifications to meet diverse application needs.

1. Materials & Key Specifications

1.1 Materials

Available in three main types of metal plates to suit different environmental and performance requirements:

Stainless steel plates

Galvanized steel plates (core material for this product, offering enhanced corrosion resistance)

Aluminum alloy plates

1.2 Thickness

Range: 0.1mm - 25mm (adjustable based on load-bearing and application scenarios)

1.3 Hole Diameter

Range: 0.25mm - 200mm (precise punching ensures uniform hole size for consistent filtration or support effects)

1.4 Dimensions

Standard sizes:

1000mm × 20000mm

1220mm × 2440mm

1250mm × 2500mm

Custom specifications (size, hole pattern) are available to match specific project requirements.

2. Core Applications

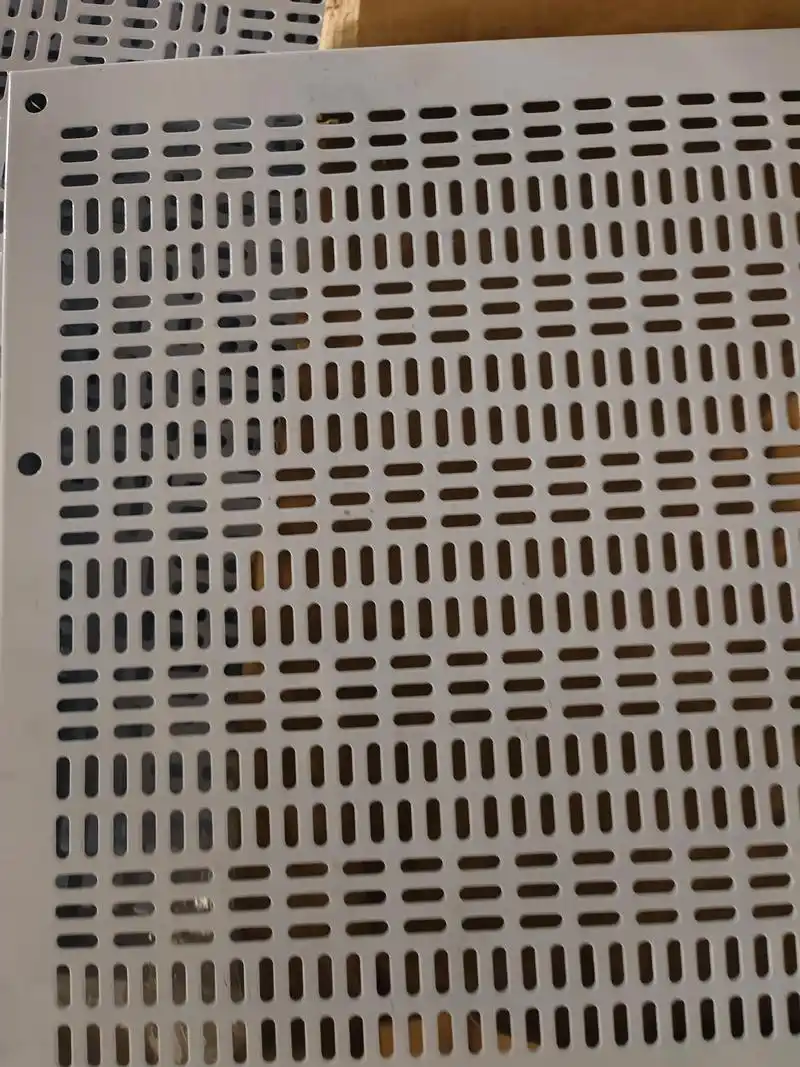

The primary application of Galvanized Perforated Mesh lies in the manufacturing of filtration and support components, including:

Support tubes for air filters, hydraulic filter elements, and dust removal filters (providing stable structural support to prevent filter media deformation).

Multi-layer filters: It can be processed via single-layer welding or multi-layer welding. After welding, layers are overlapped and inserted into filter tubes to form multi-layer filters, improving filtration efficiency and extending service life.

3. Special Product: Perforated Mesh Cylinders

Perforated Mesh Cylinders are a specialized form of Galvanized Perforated Mesh, designed for cylindrical filtration and support scenarios.

3.1 Manufacturing Process

Perforation: Metal mesh strips are punched according to customer-specific hole patterns and sizes.

Forming: The perforated mesh strips are bent into a spiral shape to form the cylindrical structure.

Welding: TIG (Tungsten Inert Gas) welding is applied to secure the spiral joints, ensuring the cylinder’s integrity and airtightness.

3.2 Materials (for High-Performance Scenarios)

304 stainless steel

304L stainless steel (low-carbon variant, better corrosion resistance)

316 stainless steel (enhanced resistance to acids and alkalis)

316L stainless steel (low-carbon 316 variant, suitable for harsh chemical environments)

3.3 Application Fields

Widely used in industries requiring high-precision filtration and strong support:

Oil extraction: Serves as oil sand control pipes (preventing sand from entering the extraction system) and filter element frameworks.

Chemical industry: Used in chemical fluid filtration and separation equipment.

Sewage treatment: Applied in wastewater purification systems for solid-liquid separation.

Water purification: Integrated into water treatment equipment to filter impurities.

3.4 Product Advantages

High supporting capacity: Maintains shape stability under pressure.

Excellent roundness & straightness: Ensures a perfect fit with matching equipment.

Customizable: External dimensions and filtration precision can be tailored to user requirements, maximizing compatibility with specific projects.

Product consultation

WhatsApp

WhatsApp